Historic Guns of British India: Difference between revisions

Symorsebrown (talk | contribs) No edit summary |

|||

| (44 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{TOC right}} | {{TOC right}} | ||

{{Template:Origin|text=This article describes some famous artillery pieces with connections to the era of the British in India.<br>The information and images have been provided by Elizabeth Hancox, FIBIS member and | {{Template:Origin|text=This article describes some famous artillery pieces with connections to the era of the British in India. See also article [[British Guns in Burma]].<br>The information and images have been provided by Elizabeth Hancox, a FIBIS member with a special interest in artillery, and the [http://www.angloburmeselibrary.com/ Anglo-Burmese Library]. }} | ||

[[Image:0001 Woolwich Barracks.jpg|600px|thumb|left|The Barracks of the Royal Arsenal Woolwich]]<div style="clear:both"></div> | |||

== The Celebrated Bhurtpore Gun at Woolwich== | == The Celebrated Bhurtpore Gun at Woolwich== | ||

[[Image:0003 Bhurtpore Gun.jpg|350px|thumb|right|Bhurtpore gun]] | [[Image:0003 Bhurtpore Gun.jpg|350px|thumb|right|Bhurtpore gun]] | ||

[[Image:0004 Bhurtpore Gun.jpg|250px|thumb|Bhurtpore gun]] | [[Image:0004 Bhurtpore Gun.jpg|250px|thumb|Bhurtpore gun]] | ||

Named | Named ‘’’"The Father of Victory"''' this gun, captured during the [[Siege of Bhurtpore 1826|Siege of Bhurtpore]] in 1826, stood for many years outside the [http://en.wikipedia.org/wiki/Royal_Artillery_Barracks Royal Artillery Barracks] at Woolwich. It is 16ft 4ins long and weighs about 17.5 tons; the calibre is 8ins. Tradition has maintained that precious metals were included in its composition; but analysis of metal taken from three places dispelled this idea. The metal is variable; it contains 9% to 15% lead, with traces of arsenic and antimony; the other components are 3% to 5% of tin, and the remainder copper. It is remarkable, however, that the exterior of the breech is of a totally different metal from the body of the gun, being in fact brass, containing nearly 37% of zinc, and has been cast over the body of the gun subsequently to the first completion of it, as one of the ornamental scrolls is partly covered by it. | ||

This trophy was confided to the two corps of [[Royal Artillery]] and [http://en.wikipedia.org/wiki/Royal_Engineers Royal Engineers] by His Majesty George IV in 1828. It bears the following inscriptions: | This trophy was confided to the two corps of [[Royal Artillery]] and [http://en.wikipedia.org/wiki/Royal_Engineers Royal Engineers] by His Majesty George IV in 1828. It bears the following inscriptions: | ||

| Line 114: | Line 115: | ||

<div style="clear:both"></div> | <div style="clear:both"></div> | ||

=== Tiger Howitzer === | === Tiger Howitzer === | ||

<gallery caption= widths=" | <gallery caption= widths="250px" heights="250px" perrow="3"> | ||

Image:0010 Tiger howitzer.jpg | Image:0010 Tiger howitzer.jpg|Tiger howitzer | ||

Image:0009 Tiger howitzer.jpg | Image:0009 Tiger howitzer.jpg|Tiger howitzer | ||

Image:0010a Tipu artillery.jpg | Image:0010a Tipu artillery.jpg|Capture of Seringapatam showing one of Tipu Sultan's Tiger guns | ||

</gallery> | </gallery> | ||

| Line 146: | Line 147: | ||

=== Mughal/Sikh Artillery === | === Mughal/Sikh Artillery === | ||

<gallery | <gallery widths="300px" heights="200px" perrow="3"> | ||

Image:0013 Brass 4.75.jpg|'''Indian brass gun on its carriage''' | Image:0013 Brass 4.75.jpg|'''Indian brass gun on its carriage''' | ||

Image:0014 Brass 4.75.jpg|Alternative view | Image:0014 Brass 4.75.jpg|Alternative view | ||

| Line 161: | Line 162: | ||

By the mid 1820s ornate cannon of this type were being replaced by similar, more streamlined, types which were both lighter and easier to produce. The closest contemporary British equivalent, a brass 9-pounder introduced in 1719, weighed almost 531lbs less and was a foot shorter. | By the mid 1820s ornate cannon of this type were being replaced by similar, more streamlined, types which were both lighter and easier to produce. The closest contemporary British equivalent, a brass 9-pounder introduced in 1719, weighed almost 531lbs less and was a foot shorter. | ||

At some point in its service life, probably in the 1820s, the barrel was remounted by Sikh engineers on a Napoleonic-style split trail carriage and aiming was improved by attaching a strap around the button connected to a capstan elevating screw. | At some point in its service life, probably in the 1820s, the barrel was remounted by Sikh engineers on a Napoleonic-style split trail carriage and aiming was improved by attaching a strap around the button connected to a capstan elevating screw. | ||

=== Sutlej Guns === | === Sutlej Guns === | ||

| Line 258: | Line 258: | ||

L 3ft 9in ( 114.3 cm) 4ft 2 in (127cm) Cal 4.2in (10.7cm) wt 7cwt 8lb (359.2 kg). | L 3ft 9in ( 114.3 cm) 4ft 2 in (127cm) Cal 4.2in (10.7cm) wt 7cwt 8lb (359.2 kg). | ||

Transferred from the Royal Arsenal, Woolwich 1968. This gun together with a similar one now in the Rotunda Museum Woolwich which may have formed part of another gift, is similar in form and decoration to the above but bears the name D | Transferred from the Royal Arsenal, Woolwich 1968. This gun together with a similar one now in the Rotunda Museum Woolwich which may have formed part of another gift, is similar in form and decoration to the above but bears the name D. Presgrave and is dated 1839 (its companion at Woolwich is illustrated as fig, 85 in ‘plans of ordnance captured by the Army of the Sutledge during the campaign of 1845-46’. Drawn by Capt Ralph Smyth, Bengal Artillery.n.d) | ||

=== Bronze Tiger Mortar === | === Bronze Tiger Mortar === | ||

'''Bronze Mortar''' | '''Bronze Mortar''' | ||

| Line 275: | Line 275: | ||

=== Kurnaul 24-pounder === | === Kurnaul 24-pounder === | ||

[[Image:0037 Bronze 24-pdr.jpg|thumb|300px|24-pounder from Kurnaul]] | [[Image:0037 Bronze 24-pdr.jpg|thumb|300px|24-pounder from Kurnaul]] | ||

'''Bronze Gun 24-pounder'''<br> | '''Bronze Gun 24-pounder'''<br> | ||

Indian probably 18th century. | Indian probably 18th century. | ||

The muzzle, trunnion ends and cascable button are formed as ‘tigers heads’. Two tigers stripes appear on the chase and the reinforce rings are edged with engrailed bands in relief. The gun is unfinished, the vent has never been drilled, a cartouche on the second reinforce intended for inscription is blank, and a lump of metal below the cascable button intended to provide a fixing for an elevating screw has never been | The muzzle, trunnion ends and cascable button are formed as ‘tigers heads’. Two tigers stripes appear on the chase and the reinforce rings are edged with engrailed bands in relief. The gun is unfinished, the vent has never been drilled, a cartouche on the second reinforce intended for inscription is blank, and a lump of metal below the cascable button intended to provide a fixing for an elevating screw has never been pierced for the securing bolt. | ||

Found with another in the fort of [[Kurnaul]], Madras Presidency, about 1838 (1859 Inventory, 137, No 85). Other pieces of ordnance from the same source are in the [http://en.wikipedia.org/wiki/Rotunda_(Woolwich) Rotunda Museum Woolwich]. They were originally found concealed in the fort. From the Rotunda Catalogue 1864 it appears they were intended for the equipment of an insurrectionary force raised to drive the British out of India. | Found with another in the fort of [[Kurnaul]], Madras Presidency, about 1838 (1859 Inventory, 137, No 85). Other pieces of ordnance from the same source are in the [http://en.wikipedia.org/wiki/Rotunda_(Woolwich) Rotunda Museum Woolwich]. They were originally found concealed in the fort. From the Rotunda Catalogue 1864 it appears they were intended for the equipment of an insurrectionary force raised to drive the British out of India. | ||

| Line 352: | Line 350: | ||

== Gun at Belvoir Castle== | == Gun at Belvoir Castle== | ||

[[Image:0046 Belvoir gun.jpg|300px|right|thumb| | [[Image:0046 Belvoir gun.jpg|300px|right|thumb|Photo courtesy of Belvoir Castle]] | ||

[http://en.wikipedia.org/wiki/Belvoir_Castle Belvoir Castle] in Rutland. | [http://en.wikipedia.org/wiki/Belvoir_Castle Belvoir Castle] in Rutland. | ||

| Line 392: | Line 390: | ||

<div style="clear:both"></div> | <div style="clear:both"></div> | ||

== Background to the Casting of Iron Guns in the Weald of Sussex == | |||

''' | ''See you the dimpled track that runs all hollow through the wheat?''<br /> | ||

''Oh, that was where they hauled the guns that smote King Philip's fleet.''<br /> | |||

from 'PUCK'S SONG' by Rudyard Kipling<br /> | |||

'' | |||

</ | |||

As the population of England doubled between 1520 and 1620 more tradespeople connected with the iron industry moved into Waldron. For 150 years the Sussex Weald, known to the Romans as the Forest of Anderida, was possibly the foremost industrial area in the country. Blast furnace techniques using water-powered bellows to heat the iron ore had been imported from France and the high temperatures obtained allowed molten ore to be poured into moulds. From 1540 the first English cannon were cast in wealden furnaces. This freed the Royal Navy from dependence on foreign guns. Most of the ordnance produced had to be dragged on rough and muddy tracks on sleds or special carts drawn by teams of oxen to small coastal ports from whence they would be transported by sea to the naval dockyards at Portsmouth or Chatham. It could take over a year to cast and deliver guns, allowing for several months for a newly fired furnace to reach 'full blast'.<br /> | |||

Waldron furnace, constructed at Furnace Farm, was in operation by 1560 and remained in business for some 200 years, producing first cannonballs and iron bars ready for the forge (known as pig-iron) but by the 18th century, cannon. The water wheel powering the furnace bellows was driven by a pond fed by the millstream, and the large pond, or dam, can still be seen.<br /> | |||

<gallery caption= widths="350px" heights="350px" perrow="2"> | |||

File:0075-Furnace-House-Waldern.jpg|'''Furnace Farm, Waldron.''' This was the site of Harrison's Foundry and Furnace. Gun trunnions were marked with a 'W'. | |||

File:0076-Large-furnace-pond.jpg|'''Large furnace pond in front of the house''' | |||

</gallery> | |||

== | <gallery caption= widths="350px" heights="350px" perrow="2"> | ||

'' | File:0077-Cannon-proving-bank.jpg|'''Cannon proving bank'''. Many cannon balls have been found at the foot of the bank by metal detectors. There was an older proving bank in a nearby wood. | ||

File:0078-Upstream-from-boring-mill.jpg|'''Site of the Boring Mill upstream.''' There are 20 tons or so of iron borings in the stream at the Boring Mill site. In the photo: Douglas Anderson, wheelwright, and Peter Davies, retired civil servant and assistant to landowner Peter Reed. Mr Davies has a special interest in muzzle loading guns such as Brown Bess. | |||

</gallery> | |||

Most landowners, particularly the Fullers, had interests in iron founding and they managed their woodland as coppice to produce the enormous amounts of charcoal needed for the blast furnaces. It has been estimated that between four and five thousand acres of coppice was needed to keep each forge and furnace combination in continuous use.<br /> | |||

The Fuller's forge at Old Heathfield was built in 1693 and lasted about a hundred years. The site is very large and has a huge man-made 'proving' bank at the base of which many cannonballs have been found. It also had a small quarry for test firing cannon and two boring mills on the stream. As at Waldron, these streams still run red with iron oxide from the massive deposits of congealed borings left in the stream beds. <br /> | |||

The | The Fullers also employed a Master Wheelwright among other highly skilled craftsmen, and interestingly there is still a fully-functioning wheelwright's shop on the site today, operated by Douglas Andrews, who has himself constructed a new gun-carriage for an Islamic trophy gun ordered by the Colonel of the Royal Engineers.<br /> | ||

The | The Fuller's forge and foundry was constructed on a particularly difficult site. If it rained too much the site would flood and if it was too dry there was a lack of fast-flowing water in the stream to generate power. In a reply dated 17th October 1754 to the Prince of San Severino, who was pressing for a firm delivery date for some guns he had ordered, John Fuller wrote: ''my furnace is a fickle mistress and must be humoured, her favours are not to be depended upon''. | ||

== The Manufacture of Gunpowder == | |||

''''To understand guns you must understand gunpowder' - Adrian B. Caruana'''<br /> | |||

[[File:Production of gunpowder.jpg|750px|left|]]<div style="clear:both"></div> | |||

Sanitary arrangements were still primitive in the reign of Henry Vlll and latrines were dug out at night by dung farmers and scavengers, but in the reign of Elizabeth l they were superseded by officials dignified by the name of Royal Saltpetre Men, who collected excrement specifically for the making of gunpowder. This was manufactured using a formula of 75 parts saltpetre, 15 parts carbon (charcoal) and 10 parts sulphur, or brimstone as it was once called. This last name is very evocative as the bright yellow sulphur was indeed collected in lumps from the brims of volcanoes in extremely hazardous conditions. The first two materials produced the explosion and the third added ignition and consistency to the grains of black powder which was milled to the size of corn, hence the name 'corned' powder, as opposed to fine powder. Fine powder was needed to prime the cannons and was also used for small arms.<br /> | |||

<gallery caption= widths="200px" heights="200px" perrow="3"> | |||

File:0080 Weir.jpeg|Weir | |||

File:0081 Millstone.jpeg|Millstone | |||

File:0082 Millstones.jpeg|Millstones | |||

File:0083 Remains of wharf.jpeg|Remains of wharf | |||

File:0084 Mill.jpeg|Mill | |||

File:0085 Remains of Corning House and Mixing House.jpeg|Remains of Corning House and Mixing House | |||

</gallery> | |||

The quantities of gunpowder loaded onto an 80 gun ship varied according to the theatre of war but would be about 288 barrels of cannon powder and 41 barrels of fine powder. Each barrel weighed 90lbs. Gunpowder was not used loose, but made up into cartridges, first of parchment and later of special cartridge paper. The method of priming a cannon was as follows: The cartridge of gunpowder would be placed down the muzzle, rammed home using a ramrod, wadded, and then the cannonball similarly. A sharp-pointed metal rod would be inserted into the vent to pierce the cartridge and the vent would then be filled up with fine powder. A portfire rod would be used to ignite the fine powder in the vent. This in turn ignited the cartridge, the resultant heat causing the gases generated to speedily build up into an explosive power sufficient to propel the cannonball up the barrel towards the target at high speed. The optimum amount of gunpowder needed per cartridge for a 32-pounder cannon would be 14lbs (1 stone). Any excess could cause such a massive build-up of gases in the barrel thereby risking the destruction of the cannon and probably most of those attending upon it.<br /> | |||

The | The gunpowder mills at Chilworth near Guildford were founded by the East India Company in 1625. They were forced to leave their previous site near Woolwich because frequent explosive accidents caused havoc among the local population. There were, of course, accidents at Chilworth but it was not a heavily populated area. On one occasion a spark from a workman's hobnailed boot striking on a stone path caused an explosion which killed six men. The mills used the fast-flowing Tillingbourne stream to power the heavy grinding stones of the incorporating process. There were many stages involved in the manufacture and thus it was very labour-intensive. As far as the ingredients were concerned, local alder trees provided the finest charcoal, sulphur was imported from Sicily, and saltpetre imported from India cost £45 per ton. A sufficient supply to last seven years in July 1752 cost £9,000. The discovery that saltpetre could be manufactured from earth gathered from dovecots, to which dung, urine and lime were added, meant that it could be collected locally. | ||

The | The 12th to 13th century chapel of St. Martha's built on a 600ft hill above the mill and half a mile distant, was considerably reduced by successive explosions, finally to a heap of stones, and only rebuilt in 1850. A massive explosion later on split the mill walls open, shattered the glass in the windows of the ancient manor and even severely damaged the village of Albury a short distance away, not to mention the deaths of the workmen and the terrible injuries caused by the volatile black powder, ignited by the slightest friction and spark. | ||

== Sources and advice obtained for research == | == Sources and advice obtained for research == | ||

| Line 464: | Line 448: | ||

*Mr Philip McGrath - Curator, Royal Armories, Fort Nelson. | *Mr Philip McGrath - Curator, Royal Armories, Fort Nelson. | ||

*Mr Derek Gurney - 'Explosion', Museum of Naval Firepower. | *Mr Derek Gurney - 'Explosion', Museum of Naval Firepower. | ||

*Mr Paul Evans -Librarian, Firepower Museum. | *Mr Paul Evans - Librarian, Firepower Museum. | ||

*Mrs Bridget Clifford - Keeper of Records (South) Tower of London. | *Mrs Bridget Clifford - Keeper of Records (South) Tower of London. | ||

*Mr David Brown - Wealden Iron Research Group. | *Mr David Brown - Wealden Iron Research Group. | ||

*Ms Zoe Edwards - Information and Local Studies Librarian, Hastings Library. | *Ms Zoe Edwards - Information and Local Studies Librarian, Hastings Library. | ||

*Mr Peter Reed, Farmer and owner of the site of the Fullers furnace and foundry. | *Mr Peter Reed, Farmer and owner of the site of the Fullers furnace and foundry. | ||

*Mr Peter Davies, Assistant - special interest - smooth bore muzzle-loading | *Mr Peter Davies, Assistant - special interest - smooth bore muzzle-loading small arms. | ||

*Mr Douglas Andrews - Wheelwright<br /> | *Mr Douglas Andrews - Wheelwright<br /> | ||

Latest revision as of 19:03, 6 October 2017

| This article describes some famous artillery pieces with connections to the era of the British in India. See also article British Guns in Burma. The information and images have been provided by Elizabeth Hancox, a FIBIS member with a special interest in artillery, and the Anglo-Burmese Library. |

The Celebrated Bhurtpore Gun at Woolwich

Named ‘’’"The Father of Victory" this gun, captured during the Siege of Bhurtpore in 1826, stood for many years outside the Royal Artillery Barracks at Woolwich. It is 16ft 4ins long and weighs about 17.5 tons; the calibre is 8ins. Tradition has maintained that precious metals were included in its composition; but analysis of metal taken from three places dispelled this idea. The metal is variable; it contains 9% to 15% lead, with traces of arsenic and antimony; the other components are 3% to 5% of tin, and the remainder copper. It is remarkable, however, that the exterior of the breech is of a totally different metal from the body of the gun, being in fact brass, containing nearly 37% of zinc, and has been cast over the body of the gun subsequently to the first completion of it, as one of the ornamental scrolls is partly covered by it.

This trophy was confided to the two corps of Royal Artillery and Royal Engineers by His Majesty George IV in 1828. It bears the following inscriptions:

On the Chase:

| ‘The Father of Victory’ | title borne by Shah Alam also |

| ‘The Reviver of Religion’ | title peculiar to Aurangzeb |

| ‘Muhammad, Aurangzeb, Alamgir' | Extolled, Throne adoring, World subduing |

| ‘The Warrior, the Victorious King’ | titles common to all Mogul emperors |

On the Swell:

| ‘Year of the Hejira 1087’ | common era AD 1677 |

| ‘The 20th of the Reign’ | Aurangzeb's reign |

Under the right trunnion:

‘The gun, the aid of Ali’

Ali, the hero-saint of the Indian Mohammedans, invoked by them in every difficulty, and especially in battle.

His titles are: ‘The victorious Lion of God,’ ‘The Remover of Difficulties

Under the left trunnion

According to the weights of Shah Jehan

The Ball, 30 sirs

Powder, 13 sirs

The weights and measures, as established by the Emperor Shah Jehan are those still used in India - the sir is about 2lbs.

The meaning of Shah Jehan is ‘King of the world’

Letters from letter-book in DAQM General’s Office, Woolwich

- 21st October 1828

- The Master General has the highest satisfaction in communicating to the Regiment of Artillery the following letter from the principal aide-de-camp to the King, conveying His Majesty’s gracious intention that the gun taken at Bhurtpoor, and presented to His Majesty by Viscount Combermere and the forces which captured that fortress, shall be mounted at the front of the barracks at Woolwich, and placed in the charge and custody of the corps of Royal Artillery and Engineers, as a special mark of His Majesty’s approbation of their services on all occasions.

- His Lordship in communicating to the two corps the King’s gracious commands, feels assured that a memorial so lasting of His Majesty’s distinguished favour will be a stimulus to continue for the future that zeal, good conduct and exertion, which has gained the corps the highest honour- the approbation of their sovereign.

- The Commandant at Woolwich is desired to take measures tp carry into effect His Majesty’s most gracious intention.

- (signed)

- A Dickson, Colonel,

- D.A. General.

- Royal Lodge, Windsor

- 13th October 1828

- My Lord

- Having, by desire of Lieut. General Cuppage, submitted to the King a drawing of the gun taken at Bhurtpoor, mounted at Woolwich, and presented to His Majesty by General Viscount Combermere and the troops of His Majesty’s and the East India Company’s Service which co-operated under his lordship’s command in the assault and capture of that fortress, and having solicited the King’s pleasure with respect of the situation in which this gun should be placed, I have been honoured with His Majesty’s commands to convey to your lordship, and to desire that you will communicate to the officers of the Royal Artillery and Royal Engineers, His Majesty’s determination that this gun shall be placed in front of the barracks at Woolwich: and His Majesty further desires that your lordship will take the necessary steps for giving due effect to such his pleasure.

- His Majesty is influenced upon this occasion, and not only by a wish to assign a public and conspicuous situation to this splendid memorial of the enterprise and gallantry of the officers and soldiers by whom the important conquest of Bhurtpoor was achieved, but also by desire to place it in the charge and custody of a body of men which has in so eminent a degree merited His Majesty’s attachment and his approbation, by its distinguished ability and gallantry on every service in which it has been engaged, and by the manner in which it has in all other respects upheld the character and credit of the British arms.

- I have &c.,

- (signed)

- H Taylor

- Principal Aide-de-camp to the King

- General Lord Viscount Beresford, G.C.B.

Guns at the Royal Arsenal

The Royal Artillery Museum at the Royal Arsenal site at Woolwich.

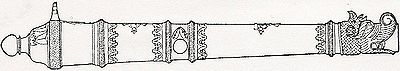

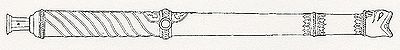

Indian SB Bronze Gun

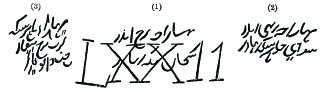

This gun captured during the Siege of Bhurtpore in 1826, was cast in 1780 and stands outside the Royal Arsenal at Woolwich. The extreme length of this gun is 168.6ins and the estimated weight 6.5 tons, calibre 5.5ins. The workmanship is both elaborate and beautiful; there are three inscriptions on this cannon, shown below as 1, 2 and 3

- 1. Translates as ‘Maharajah Brijander Sujjan Singh Bahadur’ which is assumed to be the name of a monarch.

- 2. This reads ‘Maharajah Pirthi Andar Siwai Jawahir Singh Bahadur or Maharajah Briji Andar Siwai Jawahir Singh Bahadur, the latter being preferred and is again the name of a monarch.

- 3. This has been more difficult to decipher but assumed to read ‘Maharao Manbhir Singh tup-i-burj-i-in Maqam Sakt Walu Kari-gar which translates to ‘Maharao Manbhir Singh made the cannon of the citadel of this place Walu was the artificer’.

The figures LXXII are obviously the work of some European, and are in no way connected with the writing.

In endeavouring to decide the history of the gun, the first thing which demands attention is the circumstance that at the end of the cascable there is the design of a face, intended apparently to represent either the sun or moon. This points strongly to the presumption that the cannon belonged to one of the dynasties known in India as the ‘Surya bunsi’ (Children of the Sun) or ‘Chandra bunsi’ (Children of the Moon). Now Udaipur was a dynasty of the sun, and the surmise that this is the state from whence the gun came is strengthened by the fact that Sujjan Singh (inscription 1) does occur in the annals of that principality; but though the British Government several times interfered in the internal administration of the country they never conducted warlike operations against the chief; so it is concluded that in spite of the mark on the cascabel, the cannon was not captured in this state.

The names ‘Siwai’ and ‘Pirthi’ (inscription 2) are to be traced to the ‘Jaipur’ dynasty, but so far as my researches have extended I cannot find that this line of Chiefs belongs to either the ‘Children of the Sun’ or ‘Children of the Moon’; moreover, though on more than one occasion the British authorities have taken steps to secure good government in this state I have not succeeded in discovering any campaign of a nature likely to result in the capture and dispatch to England of a cannon of this description; so I dismiss ‘Jaipur’ from further consideration. There remains but one other state to which I wish to refer as in any way connected with the matter at issue- I allude to ‘Bhartpur’. In the first place the ruling race is sprung from the ‘Jats’ and these in turn claim an origin as the ‘Children of the Moon’, moreover ‘Brijandar’ ‘Siwai and ‘Jawahir Singh’ are all names frequently to be met in the annals of the Bhartpur dynasty, while the first of the three as far as I can learn, is confined exclusively to this state. Further there was also a Chieftain of this kingdom called Jawahir Singh who ruled 1763-1768. Lastly, the play of words in ‘Brij’ and ‘Burj’ both written b r j (no short vowels) seem to emphasise the word ‘Brijandar. These various arguments seem to point strongly to the supposition that the cannon came from Bhartpur and dates from the third quarter of the 18th Century.

(The analysis of the cannon undertaken by Mr Wollaston of the India Office)

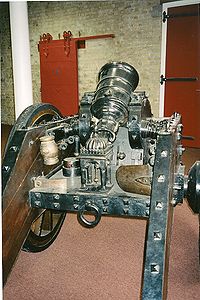

The Mulharrao Howitzer

A bronze 6’’ howitzer late 18th century from Baroda, it is mounted on a native carriage. Weight 3cwt. 34lbs; length of chamber 6.3 in; length of bore 7in. There are numerous implements attached to the brackets of the carriage.

This exceptional gun was captured by a British Force at Khuree (modern Kadi) in Gujarat in 1802 during a campaign often seen as the beginning of the second Anglo-Maratha War. Kanoji Rao, illegitimate brother of Anunt Rao, disputed his succession to the Gaikwar of Baroda. To back his own claim Khanoji enlisted the powerful support of his cousin Mulhar Rao who held the practically independent fiefdom of Kadi. Mulhar Rao raised an army of 32,000 men. In return for military assistance from the Company’s Bombay Army Anunt Rao promised territory and tax revenues to the East India Company. 6,000 British and Company troops attacked Mulhar Rao’s army and forced him to retreat. His fortress at Kadi, along with 58 guns, fell into British hands on 5th May 1802.

The Marathas developed some of the very best artillery encountered by the British. They were particularly noted for their technical innovation and the use of multi-purpose types. This gun is a hybrid mortar and howitzer. As a field Howitzer it would have fired explosive shell much like a contemporary 5.5 inch howitzer. But it was also capable of firing at even higher trajectories used by mortars in siege warfare. The carriage is stoutly built to withstand the shock of firing. One of the particularly unusual features is the plumb line within the decorative cupola, which ensured the gun was level, thus improving accuracy. Another is the iron spikes, stabilising the piece in preparation for subsequent high angle rounds.

Tiger Howitzer

- widths="250px"

-

Tiger howitzer

-

Tiger howitzer

-

Capture of Seringapatam showing one of Tipu Sultan's Tiger guns

Captured at Tipu Sultan’s fortress at the Battle of Seringapatam in 1799.

Tipu’s emblem was the tiger and he was known as ‘The Tiger of Mysore’. This piece is probably not finished as the detail of the chasing is not as fine as would normally be expected. It is a bronze 4 pounder inscribed 'Patan (Sriringpatna) Cast by Shams al-Din'. This gun is typical of those produced throughout Tipu Sultan’s region and is decorated with his emblems; tiger heads on the muzzle, trunnions and button, and the bubri, or stylised tiger stripes, which also contain information about production.

After his defeat by the British in 1792, Tippu Sultan employed French technical expertise to improve his arsenal, including the introduction of water-powered boring machines. The ornamental finish of his brass guns and mortars, noted European observers, was ‘brought to some perfection’. At the fall of Seringapatam in 1799, 927 cannon were captured. Out of approximately 400 brass guns well over half were manufactured in Tipu’s own foundry. The rest were mostly French or Dutch.

Two rectangular marks along the middle of the gun on both sides and the offset bore indicate that it was made using the cast-on construction. A separate inner mould was used for the bore and held in place by iron chaplets which remained embedded in the bronze after casting. This method of casting was first used in the 16th century, but was phased out in Europe by the late 18th century. However, it continued to be used by Indian states well into the 1830s. It may well have been for this reason that Arthur Wellesley, who was at Seringapatam in 1799, considered the quality of Tipu’s artillery to be inferior to those he later encountered in use by the Maratha army in 1803.

Cossipore Guns

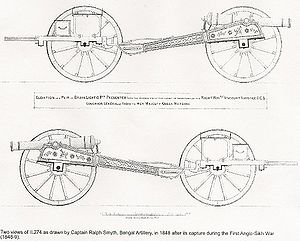

- Two views of the same presentation gun - one of a set given to Ranjit Singh - and recaptured by the British.

Bronze 9 pounder. D Presgrave, Cossipore (East India Company) 1838/39

Produced by the East India Company’s gun foundry at Cossipore near Calcutta. This cannon was one of a set intended for presentation to Maharaja Ranjit Singh by George Eden, Lord Auckland, and Governor General, on the conclusion of treaty negotiations in 1838. The guns were presented with 200 rounds of shot and shell intended for a planned Anglo-Sikh invasion of Afghanistan.

- The salute was fired by the howitzers that G. has had made to present to Ranjeet. They are very handsome, ornamented more than our soldiers think becoming, but just what Ranjeet would like; there is the bright star of the Punjab, with Ranjeet’s profile on the gun and Captain E. Says that thousand of Sikhs have been to look at these guns, and all of them salaam to Ranjeet’s picture as if it were himself.

- Emily Eden (Lord Auckland’s sister who accompanied him on his state visit to the Panjab) ‘Up the Country’; Letters from India Ch XXV, p 189

The guns were captured 7 years later in action at the Battle of Ferozeshah, not far from Ferozepore where the guns were first presented.

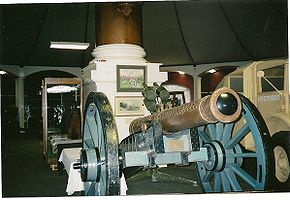

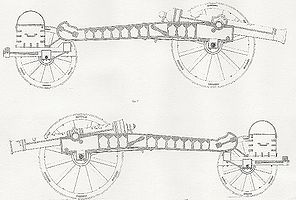

Mughal/Sikh Artillery

-

Indian brass gun on its carriage

-

Alternative view

-

Elevation as drawn by Capt. Ralph Smyth, Bengal Artillery, in 1848 after its capture during the 1st Sikh War 1845-6, Bronze 8.33 lb (7 seers), Panjab, prob Lahore, late 18th to early 19th century, Calibre 4.1

Calibre 4.75in; length of bore 7ft 7.5 in; total length 8ft 8in.

The ornamentation of this gun is peculiar and quite oriental. The carriage is decorated with thin iron plates of similar design to the ornament on the gun. The dolphins represent an animal somewhat like a rhinoceros. The vent is iron and plugged.

This is one of several cannon produced between 1760 and 1825 based on ‘Zamzamah’ or ‘Kim’s Gun’ which was cast in Lahore in 1761. It is a fine example of the Mughal casting tradition already in the Panjab before the Sikhs took over. Similar pieces have been dated to as late as 1825. The barrel is decorated in the Mughal style with palmette borders and a vase and flowers motif. The button is decorated with a lotus flower and the dolphins in the shape of makara (mythical water demons); motifs widely used in Indian art.

By the mid 1820s ornate cannon of this type were being replaced by similar, more streamlined, types which were both lighter and easier to produce. The closest contemporary British equivalent, a brass 9-pounder introduced in 1719, weighed almost 531lbs less and was a foot shorter. At some point in its service life, probably in the 1820s, the barrel was remounted by Sikh engineers on a Napoleonic-style split trail carriage and aiming was improved by attaching a strap around the button connected to a capstan elevating screw.

Sutlej Guns

Sikh Horse Artillery Light 6-pounder (5 seer) Panjab. Lahore, about 1838 Calibre: 3.25in (5.5 pounder)

Throughout Maharaja Ranjit Singh’s reign, Sikh engineers had access to East India Company patterns and workshops, as well as periodic diplomatic gifts of cannon. These accelerated artillery development to such an extent that by the late 1830’s, Sikh artillery rivalled that of the Company in both quality and quantity.

This cannon (above) is one of the finest surviving examples and clearly shows the exceptional technical and artistic expertise in the Sikh foundries and workshops. The barrel, produced in Lahore in 1838, is based on the British Light 6 pounder; the carriage on the Bengal artillery pattern introduced in 1823, but lavishly decorated with brass, copper, steel and mother-of-pearl inlay.

This cannon was almost certainly captured at the Battle of Aliwal, where four guns attributed to the work of the prominent Sikh engineer, Lehna Singh Majithia, were singled out for specific mention. It may have been made for the Fauj-l-Khas, or Royal Brigade, the elite brigade of the Sikh army. Commanded by his best French Officers, using French drill and imperial flags and eagles, it was also known as the French Brigade or the French Legion.

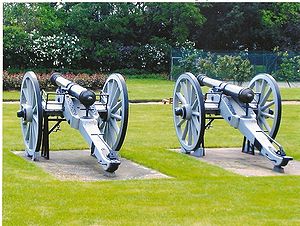

Two bronze guns captured from the Sikhs at the Battle of Moodkee on the Sutlej, 19th December 1845. Probably made at Lahore. Complete with carriages, limbers with boxes, buckets, rammers, port-fire holders, axes, etc.

Beautifully made of mahogany richly mounted with pieced brasswork and inlaid with brass, copper, steel and mother-of-pearl. Calibre, 3,25in; length, 5ft 6in.

Other guns

Two bronze guns (one shown front) from India, elaborately decorated on the upper surface. On the reinforce are the arms of the East India Company and the motto ‘AUSPICIO REGIS ET SENATUS ANGLIAE,’ on the reinforce ring is the makers name ‘G HUTCHINSON, 1838, COSSIPORE.’ And on the second gun (not shown) the makers name ‘D PRESGRAVE, 1839, COSSIPORE’ appears on the ring. On the chase of both is a collar with star, round the collar runs an Oriental inscription; they also bear inscriptions of the same character on the reinforce, as well as on another part of the chase. The vent of the second gun is enlarged to 0.5in. Calibres, 4.49 in and 4.23 in; length of bore 44.2 in; total length 51.3 in.

The second gun shown at the rear of the picture is brass 12-pr gun of the late East India Company, with the arms and motto of the Company-‘AUSPICIO REGIS ET SENATUS ANGLIAE G HUTCHINSON, 1839, COSSIPORE CXLIX’ and the letter ‘p’ on the reinforce ‘No 149’ on button. No dolphins. Calibre 4.55in; length, 3ft. 91/2 in; weight, 6cwt. 80lbs

- One of three Indian bronze guns

-

Might date from about 1675 ( late Mughal) but the carriage with its elevating screw dates from 1859. (Brig. Young). No further information available.

Bronze gun from India, slightly ornamented about the cascable and chase. Calibre 4.86 in; length of bore, 7ft 10.5 in; total length 8ft 9 in; weight 15cwt 19lbs. The gun is supposed to have been carried into Assam by the Musselmans at the time of the invasion of the province by the Mahomedan power, and to have been taken from them by the Assamese at the time of their expulsion, or rather disastrous retreat from the malarias effects of the climate. It is well known they left a number of guns behind them.

The guns seem to have been manufactured by a European, as it has an inscription in the roman character, ‘EVERHARDVS. SPLINTER.ME. FECIT ENGHVSAE. ‘The date on the reinforce is 1629. In Persian there is also an inscription which bears the name of the reigning Mahomedan sovereign, with the date of the manufacture. There is a third inscription on the gun in either Assamese or Ahom, stating the name of one Assam King, by whom, and the date when the gun was taken by the Assamese.

- widths="300px"

-

Fine chainmail coat with hood. Would have been worn with armour and helmet in mediaeval style, probably by fanatical Sikh horsemen called Gorchuras who went into battle, drug crazed, during the Punjab Campaigns of the 1840s and earlier. Also worn by MULRAJ-Diwan of Multan in the first battle of the 2nd Sikh War 1848. 'Sometimes he talks of a night attack, and sits up all night in a Hindu temple near the bridge cased in his chain armour from head to foot……. .' <ref>from Six Battles for India: Anglo-Sikh Wars, 1845-46 and 1848-49 by George Bruce 1969 ISBN 10: 021317796X ISBN13: 978-0213177966.

-

Smaller bronze gun from Lucknow, bearing the Oude emblem of the fish; there is an inscription on the reinforce, and ‘By Major Claud Martin, Lucknow’ on the base ring. Calibre, 3.68in; length of bore, 46.4; total length 55in.

-

Indian 4 pounder. 3.1 in calibre, circa 1820. There appear to be tiger’s heads on the trunnions.

-

A brass gun brought from Scinde. It is richly ornamented. There is a curious representation of the head of an animal on the muzzle. On the chase are two blank scrolls. The dolphins represent fish. Length, 4ft 8 in; calibre, 3.42 in.

Guns at Fort Nelson

These guns are at the Royal Armouries Museum Fort Nelson Fareham

Sutlej Campaign 6-pounder

- widths="200px"

-

Indian gun 6-pounder. Captured from the Sikhs during the Sutlej Campaign c1845. Field gun, British pattern- Horse Artillery.

-

Acquired from the family of Sir Hugh Gough who finally defeated the Sikhs in the 2nd Sikh War 1849 at Gujrat. Carriage decorated with two figures of Sikhs, possibly representing Ranjit Singh himself.

-

Cutter from 6-pounder in form of peacock.

-

Trail arm hook on limber ornamented with small brass figure representing mahout.

Mountain Battery Swivel Gun

- widths="300px"

-

Punjab Mountain Battery. Model showing ‘swivel’ gun barrel on mule and officer and men drawn from various regiments.

-

Bronze ‘swivel’ gun screwed together and mounted on carriage. Wheels bound in bronze.

Sikh bronze 7-pounder

- widths="300px"

-

Sikh bronze gun on carriage.

-

Second view.

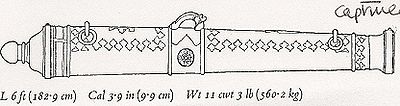

Bronze gun, 7-pounder and carriage. Indian. Late 18th century; carriage, Indian (?), 19th century

This piece is decorated with palmette ornament in relief and there are cartouches with inscriptions in northwest Indian script, now practically illegible. The gun is equipped with a pair of lifting rings at breech and muzzle and also dolphins; the base ring is stamped with the weight 11-0-3 and the cascable is numbered 7. Two small blocks form a fore sight and a rear sight.

Said to have been captured at Chillianwala but now thought to be Sutlej.

British 9-pounder Howitzer

Bronze Gun or Howitzer, 9-pounder (PL.52) Indian, Cossipore dated 1838.

The surface is decorated in relief with bands of conventialised foliage edging rings which, with the exception of the vent astragal, are flat. On the first reinforce in relief are the arms, with crest, supporters and motto, of the East India Company. The second reinforce bears a cartouche engraved with Persian verse inscription which reads:

What a fine brass barrel with roaring muzzle. This muzzle is like that of a destructive lion. This splendid gift which Lord Auckland, Governor-in-Chief (Governor-General), brought to Hindustan which at the behest of friendship he ordered as a present for Maharajah Ranjit Singh. To date this majestic voice, men said ‘Show forth the day of victory.

The letters making up the last phase also form a chronogram giving date of manufacturing according to Christian reckoning 1838. Between the lines of verse are three words meaning ‘Christian religious (era)183(8).’ The chase bears a representation of the Order of the Bright Star of the Punjab, a decoration instituted by Ranjit Singh towards the end of his reign. The decoration is shown attached to a ribbon, this being inscribed in Pujabi written in Persian script: ‘Noble great King of Kings! Maharajah Ranjit Singh Bahadur. In the year 1895.’ This date in the Vikram Samvat era is equivalent to 1838. The first reinforce ring is inscribed G HUTCHINSON, 1838. COSSIPORE. The second reinforce ring bears the number 11 on either side of which is also engraved in Persian script ‘this piece of artillery was named Khorehnal’ (devouring gun). There is a disport patch at the muzzle and a block on the cascable which is drilled for a central rear sight and stamped with the number 70. The weight 7-0-8 is stamped on the base ring.

L 3ft 9in ( 114.3 cm) 4ft 2 in (127cm) Cal 4.2in (10.7cm) wt 7cwt 8lb (359.2 kg).

Transferred from the Royal Arsenal, Woolwich 1968. This gun together with a similar one now in the Rotunda Museum Woolwich which may have formed part of another gift, is similar in form and decoration to the above but bears the name D. Presgrave and is dated 1839 (its companion at Woolwich is illustrated as fig, 85 in ‘plans of ordnance captured by the Army of the Sutledge during the campaign of 1845-46’. Drawn by Capt Ralph Smyth, Bengal Artillery.n.d)

Bronze Tiger Mortar

Bronze Mortar Indian, probably late 18th century.

The piece is cast in the form of a sitting tiger, the muzzle issuing from open jaws, the surface being modelled and chased to simulate stripes. It appears to be unfinished since the vent is not drilled and the bore has not been cleaned after casting. There is a lifting loop at the front, on the under side.

L 4ft 6in (137.2cm) Cal 9.4in ( 23.9cm) Diam chamber 7.2in (18.3cm)

Found concealed in the Fort at Kurnaul, Madras Presidency, in 1838 together with 219qv.

There is a similar mortar, also from Kurnaul, at the Firepower Museum.

Kurnaul 24-pounder

Bronze Gun 24-pounder

Indian probably 18th century.

The muzzle, trunnion ends and cascable button are formed as ‘tigers heads’. Two tigers stripes appear on the chase and the reinforce rings are edged with engrailed bands in relief. The gun is unfinished, the vent has never been drilled, a cartouche on the second reinforce intended for inscription is blank, and a lump of metal below the cascable button intended to provide a fixing for an elevating screw has never been pierced for the securing bolt.

Found with another in the fort of Kurnaul, Madras Presidency, about 1838 (1859 Inventory, 137, No 85). Other pieces of ordnance from the same source are in the Rotunda Museum Woolwich. They were originally found concealed in the fort. From the Rotunda Catalogue 1864 it appears they were intended for the equipment of an insurrectionary force raised to drive the British out of India.

Bhurtpore 6-pounder

Bronze Gun 6-pounder

Indian, early 18th century

The bore is sleeved with an iron tube constructed of welded parallel strips. There is a band of conventional flowers and foliage by the trunnions and on the base ring, the cascable being stylised lotus form. Diamond-shaped cartouches on the second reinforce and on the chase frame Hindu names and Hindi titles in Persian inscriptions. These are much worn and in parts illegible, but they appear to state that the gun was made to order of the ‘Earth-lord Maharajah Sava’i Jai Bahadur’. The base ring carries a back sight. By the vent, the first reinforce is incised with the number LXIII and 67-0-0, the latter probably the weight. Further forward is stamped ANO 24 6Pr. These markings were added after the capture of the gun.

L11ft 4in (345.4cm): 12ft 8in (386.1cm) Cal 3.75in (9.5cm) Wt 67cwt(3403.6kg)

Captured at Bhurtpore in 1826 by General Viscount Combermere, later Field Marshal and Constable of the Tower. Presented by the East India Company in 1856 (1859 inventory, xix 78). The inscriptions show that this gun was cast to the order of Sava i Jai Singh, ruler of Amber (modern Jaipur) from 1693 to 1743. He was the founder of Jaipur and is famous for the astronomical observatories which he built in various places in N. India.

Indian bronze 2-pounder

Bronze Gun 2-pounder

Indian, 18th century

The muzzle is formed as a monster’s head. The prominent mouldings are edged with conventional foliage, the chase and second reinforce being ornamented with foliated panels in relief. A raised block on the base ring is pierced with a peep sight, there being a large fore sight at the muzzle. The chase is engraved with the measurements: ‘Length 10 in 5, width 2in 5, 10’. Just below the first reinforce ring are stamped the numbers 59-4-2-25, the first being an inventory number, the other its weight. The entire surface shows considerable traces of gold paint.

L 5ft ( 152.4cm): 5ft 8.5in (174cm) Cal 2.3in (5.8cm) Wt 4cwt 2 qtr 25lb (239.9Kg)

Transferred from the India Office to the Indian Section of the Victoria & Albert Museum, in 1894, and from the Museum to the Armouries in 1958.

Burmese Dragon Gun

Taken by British forces in 1885 from King Thebaw’s Palace in Mandalay.

Guns at the Royal Hospital

The Royal Hospital in Chelsea.

Indian 6-pounder

BRONZE GUN, 6-pounder and carriage (PL.42)

Indian, dated 1790-1; carriage, Indian (?), 19th century.

This gun is on the terrace of the Royal Hospital at Chelsea in a line up of 4 guns all painted over black/grey!

The breech and muzzle are ornamented with raised bands of palmette-type decoration. The reinforces have raised panels engraved with inscriptions in Devanagari and Persian lettering which are now partly illegible but the Devangari inscription includes the date, the Vikrum Samvat year 1848 = 1790-1, and the Persian inscription appears to refer to the weights of powder and shot. The base ring is stamped with the weight of the piece 12-0-21 and the cascable bears the number 27.

L6ft 7in (200.7cm) Cal 3.7 in (9.4cm) Wt 12 cwt 21lb (619.1kg)

Believed to have been taken at the Battle of Chillianwallah 1849. Presented to the Royal Hospital Chelsea by the East India Company in 1856. Transferred to the Armouries in 1925, but remaining on loan to the Hospital

It has now been dated by Mathew Buck (Firepower Museum Woolwich) and Neil Carlton (V&A) from 1st Sikh War 1845-46. It is the only example seen of ‘standard munition quality’ Sikh field carriage.

17th Century Chinese Guns

Two Chinese guns incorrectly labelled at Chelsea as Sikh and taken at Chillianwalla during the 2nd Sikh war.

These guns were 2 of a set of 4 placed around the Chillianwala Memorial on the Embankment. 2 of the 4 were genuine Sikh guns and these 2 were ‘faked’ by the Armouries to appear Sikh simply because they were short of the genuine articles!

The carriages are of similar construction. Each has a solid trail with a hinged traversing lever and elevating screw. There are two axle-tree seats with chain foot rests. These carriages are based on English field carriage of around 1850 and are similar to the others, a distinctive feature on all being the axle hubs cast as stylised tigers heads.

Transferred to the Armories in 1925 but still on loan to the Royal Hospital, Chelsea. The original loan being in 1875 from the Royal Arsenal, Woolwich.

Father Ferdinand Verbiest 1623-88, a Jesuit priest of Flemish birth, was sent to China as a missionary in 1657 and, in 1677, became Vice-Provincial of the Order. He was held in great favour by the Emperor K’ang-hsi for whom he carried out many tasks of a scientific and mathematical nature. Amongst other achievements he designed and supervised the manufacture of three hundred cannon which he blessed giving each one the name of a saint. The fact that the date of the casting of no. 203 is a year later than Verbiest’s death may be explained by their being part of a series whose manufacture commenced the previous year. Another of Verbiest’s guns, also date 1689 and bearing a similar inscription, is in Hakozaki Shrine, Kiyushu, Japan (Shin-ichi Yoshioka, Collection of Antique Guns Tokyo 1965, 36)

Gun at Belvoir Castle

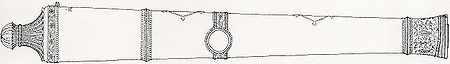

Belvoir Castle in Rutland.

Assumed to have been presented by Henry, Ist Viscount Hardinge, to the 5th Duke of Rutland and said to have been captured during the 2nd Sikh War (1848-49) possibly at Multan.

It is of archaic appearance and seems to be 17th or 18th century in style.

It is remarkably similar to the drawing of the swivel gun below.

L 4ft 4.5in (133.4cm); 4ft 9in (144.8cm) Cal 1.6in (4cm) Wt 1cwt 2 qtr (76.2kg)

Bronze Gun

Indian, probably 17th century

The gun is intended for a swivel mounting. The muzzle is in the form of a tiger’s head, the reinforce being decorated with raised diagonal ribs radiating from a central rib possibly simulating a tiger’s stripes. There is a slot at the breech for a back sight now missing, the vent being placed slightly to the right side. The cascable button is formed as a tube, octagonal outside with a square bore, pierced for a transverse pin; it is intended to form a socket for a tail or aiming lever. The chase is engraved with several inscriptions in Arabic script; one is properly engraved to read ‘The wise Almighty’, the others are in the nature of graffiti.

There is a remarkable similarity between this gun and the one photographed above.

Taku Fort Gun

The Taku Forts were defences near Tianjin in northeastern China.

An ‘Armstrong’ rifled muzzle loader. It was possibly placed in the old fort during the 3rd China War|Boxer Rebellion 1896-1901. Calibre estimated at 7-10 in. British guns of this type were not manufactured until the late 1870s.

The photograph was taken in 1928 by Terence Shields Marshall (b Calcutta 1904) in one of General Gordon’s Taku forts built at the time of the Taiping Rebellion 1850-64.

The Zamzamah (Kim's Gun) Lahore

The Zamzama is currently in front of the Lahore Museum, in Lahore, Pakistan.

For an online edition of Kim, refer Rudyard Kipling.

This gun at 14ft 4.5 in bore 9.5in cast at Lahore in 1757 and used by Ahmed Shah Abdali, the Afghan, against the Marathas in a combined operation with the Mughals in 1761 at the Battle of Panipat, and subsequently by Ranjit Singh in 1818 in his final successful effort to subdue Multan, City and Fort. The gun blasted the walls with 80lbs shot.

Background to the Casting of Iron Guns in the Weald of Sussex

See you the dimpled track that runs all hollow through the wheat?

Oh, that was where they hauled the guns that smote King Philip's fleet.

from 'PUCK'S SONG' by Rudyard Kipling

As the population of England doubled between 1520 and 1620 more tradespeople connected with the iron industry moved into Waldron. For 150 years the Sussex Weald, known to the Romans as the Forest of Anderida, was possibly the foremost industrial area in the country. Blast furnace techniques using water-powered bellows to heat the iron ore had been imported from France and the high temperatures obtained allowed molten ore to be poured into moulds. From 1540 the first English cannon were cast in wealden furnaces. This freed the Royal Navy from dependence on foreign guns. Most of the ordnance produced had to be dragged on rough and muddy tracks on sleds or special carts drawn by teams of oxen to small coastal ports from whence they would be transported by sea to the naval dockyards at Portsmouth or Chatham. It could take over a year to cast and deliver guns, allowing for several months for a newly fired furnace to reach 'full blast'.

Waldron furnace, constructed at Furnace Farm, was in operation by 1560 and remained in business for some 200 years, producing first cannonballs and iron bars ready for the forge (known as pig-iron) but by the 18th century, cannon. The water wheel powering the furnace bellows was driven by a pond fed by the millstream, and the large pond, or dam, can still be seen.

- widths="350px"

-

Furnace Farm, Waldron. This was the site of Harrison's Foundry and Furnace. Gun trunnions were marked with a 'W'.

-

Large furnace pond in front of the house

- widths="350px"

-

Cannon proving bank. Many cannon balls have been found at the foot of the bank by metal detectors. There was an older proving bank in a nearby wood.

-

Site of the Boring Mill upstream. There are 20 tons or so of iron borings in the stream at the Boring Mill site. In the photo: Douglas Anderson, wheelwright, and Peter Davies, retired civil servant and assistant to landowner Peter Reed. Mr Davies has a special interest in muzzle loading guns such as Brown Bess.

Most landowners, particularly the Fullers, had interests in iron founding and they managed their woodland as coppice to produce the enormous amounts of charcoal needed for the blast furnaces. It has been estimated that between four and five thousand acres of coppice was needed to keep each forge and furnace combination in continuous use.

The Fuller's forge at Old Heathfield was built in 1693 and lasted about a hundred years. The site is very large and has a huge man-made 'proving' bank at the base of which many cannonballs have been found. It also had a small quarry for test firing cannon and two boring mills on the stream. As at Waldron, these streams still run red with iron oxide from the massive deposits of congealed borings left in the stream beds.

The Fullers also employed a Master Wheelwright among other highly skilled craftsmen, and interestingly there is still a fully-functioning wheelwright's shop on the site today, operated by Douglas Andrews, who has himself constructed a new gun-carriage for an Islamic trophy gun ordered by the Colonel of the Royal Engineers.

The Fuller's forge and foundry was constructed on a particularly difficult site. If it rained too much the site would flood and if it was too dry there was a lack of fast-flowing water in the stream to generate power. In a reply dated 17th October 1754 to the Prince of San Severino, who was pressing for a firm delivery date for some guns he had ordered, John Fuller wrote: my furnace is a fickle mistress and must be humoured, her favours are not to be depended upon.

The Manufacture of Gunpowder

'To understand guns you must understand gunpowder' - Adrian B. Caruana

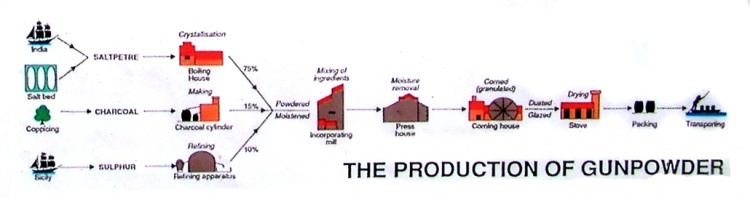

Sanitary arrangements were still primitive in the reign of Henry Vlll and latrines were dug out at night by dung farmers and scavengers, but in the reign of Elizabeth l they were superseded by officials dignified by the name of Royal Saltpetre Men, who collected excrement specifically for the making of gunpowder. This was manufactured using a formula of 75 parts saltpetre, 15 parts carbon (charcoal) and 10 parts sulphur, or brimstone as it was once called. This last name is very evocative as the bright yellow sulphur was indeed collected in lumps from the brims of volcanoes in extremely hazardous conditions. The first two materials produced the explosion and the third added ignition and consistency to the grains of black powder which was milled to the size of corn, hence the name 'corned' powder, as opposed to fine powder. Fine powder was needed to prime the cannons and was also used for small arms.

- widths="200px"

-

Weir

-

Millstone

-

Millstones

-

Remains of wharf

-

Mill

-

Remains of Corning House and Mixing House

The quantities of gunpowder loaded onto an 80 gun ship varied according to the theatre of war but would be about 288 barrels of cannon powder and 41 barrels of fine powder. Each barrel weighed 90lbs. Gunpowder was not used loose, but made up into cartridges, first of parchment and later of special cartridge paper. The method of priming a cannon was as follows: The cartridge of gunpowder would be placed down the muzzle, rammed home using a ramrod, wadded, and then the cannonball similarly. A sharp-pointed metal rod would be inserted into the vent to pierce the cartridge and the vent would then be filled up with fine powder. A portfire rod would be used to ignite the fine powder in the vent. This in turn ignited the cartridge, the resultant heat causing the gases generated to speedily build up into an explosive power sufficient to propel the cannonball up the barrel towards the target at high speed. The optimum amount of gunpowder needed per cartridge for a 32-pounder cannon would be 14lbs (1 stone). Any excess could cause such a massive build-up of gases in the barrel thereby risking the destruction of the cannon and probably most of those attending upon it.

The gunpowder mills at Chilworth near Guildford were founded by the East India Company in 1625. They were forced to leave their previous site near Woolwich because frequent explosive accidents caused havoc among the local population. There were, of course, accidents at Chilworth but it was not a heavily populated area. On one occasion a spark from a workman's hobnailed boot striking on a stone path caused an explosion which killed six men. The mills used the fast-flowing Tillingbourne stream to power the heavy grinding stones of the incorporating process. There were many stages involved in the manufacture and thus it was very labour-intensive. As far as the ingredients were concerned, local alder trees provided the finest charcoal, sulphur was imported from Sicily, and saltpetre imported from India cost £45 per ton. A sufficient supply to last seven years in July 1752 cost £9,000. The discovery that saltpetre could be manufactured from earth gathered from dovecots, to which dung, urine and lime were added, meant that it could be collected locally.

The 12th to 13th century chapel of St. Martha's built on a 600ft hill above the mill and half a mile distant, was considerably reduced by successive explosions, finally to a heap of stones, and only rebuilt in 1850. A massive explosion later on split the mill walls open, shattered the glass in the windows of the ancient manor and even severely damaged the village of Albury a short distance away, not to mention the deaths of the workmen and the terrible injuries caused by the volatile black powder, ignited by the slightest friction and spark.

Sources and advice obtained for research

People

- Mr Philip McGrath - Curator, Royal Armories, Fort Nelson.

- Mr Derek Gurney - 'Explosion', Museum of Naval Firepower.

- Mr Paul Evans - Librarian, Firepower Museum.

- Mrs Bridget Clifford - Keeper of Records (South) Tower of London.

- Mr David Brown - Wealden Iron Research Group.

- Ms Zoe Edwards - Information and Local Studies Librarian, Hastings Library.

- Mr Peter Reed, Farmer and owner of the site of the Fullers furnace and foundry.

- Mr Peter Davies, Assistant - special interest - smooth bore muzzle-loading small arms.

- Mr Douglas Andrews - Wheelwright

Books

- The Age of the System 1715-1815 by Adrian B. Caruana

- Arming the Fleet - U.S. Navy Ordnance in the Muzzle-Loading Era by Spencer Tucker

- The Wealden Iron Industry by Jeremy Hutchinson, and his Dissertation for M.A.- Brighton

- The Arming and Fitting of English Ships of War, 1600-1815 by Brian Lavery

- Wealden Iron by Ernest Straker

- Weale Manuscript

- The Art of Gunfounding by Carol de Beer

- The Fuller Family Archive - Lewes Record Office

- The Fullers of Waldron, Heathfield and Brightling by Alec Parks

- Waldron, Portrait of a Sussex Village by Susan Russell, Rosalie Parker and Valerie Chidson

- The History of the Ironmongers Company by Elizabeth Glover

- Walks into History by David Weller

Libraries

- Science Library, Imperial College, London

- Public Record Office, Kew

- India Office Library and Records, British Library, London